Bridgecrest – UX/UI Design

DriveTime and Bridgecrest – Visual Design

Sacred Roots – Conceptual App/VR Design

Glidance

Designing an intuitive unboxing experience for blind users.

PROJECT TYPE:

PACKAGE DESIGN

CLIENT:

GLIDANCE

TIMELINE:

AUG. 2024 - DEC. 2024

TOOLS:

FIGMA, BLENDER, PROTOTYPE SUPPLIES

Challenge

Glidance needs a way for their customers to be able to intuitively interact with and open packaging for their mobility device, taking into account needs of blind and low vision individuals.

Solution & Impact

Our team built 25 prototypes to test, gained 35 insights from the blind and low vision community, and delivered two final packaging options on budget.

Glidance prioritizes accessibility.

situation

Glidance has created a mobility and navigational tool for the blind and low-vision community, creating a new perspective for assistive technology and design through the use of AI. They entrusted our design team here at the University of North Texas to design and create a successful packaging prototype for the product.

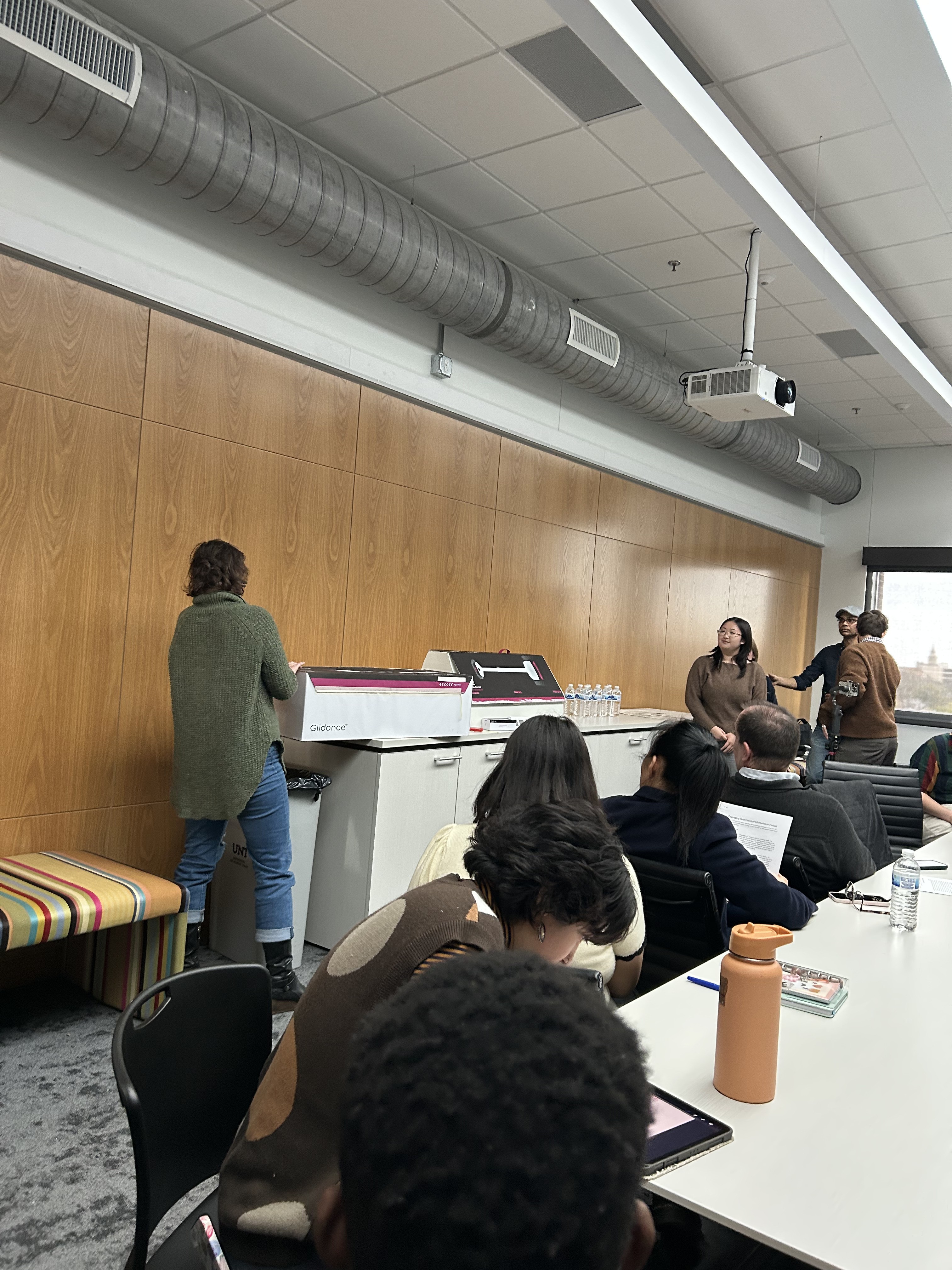

Meeting with Glidance members

Creating an accessible experience. task

Glidance tasked our team of 6 to come up with a successful packaging prototype for their Glide product launching 2025, taking into account the needs of the blind and low vision community and factors like materials, shipping, and price. The process is crucial as this experience is the first touchpoint with the product, builds trust and loyalty, and increases reputation for the company.

Initial Findings

~10%

of blind US citizens know braille

Tactile elements

play a crucial role in sensory experience

Haptics

can improve an experience involving sense of touch

Initial Takeaways

Many braille users from the Glidance community mentioned wanting Braille in their Glide experience.

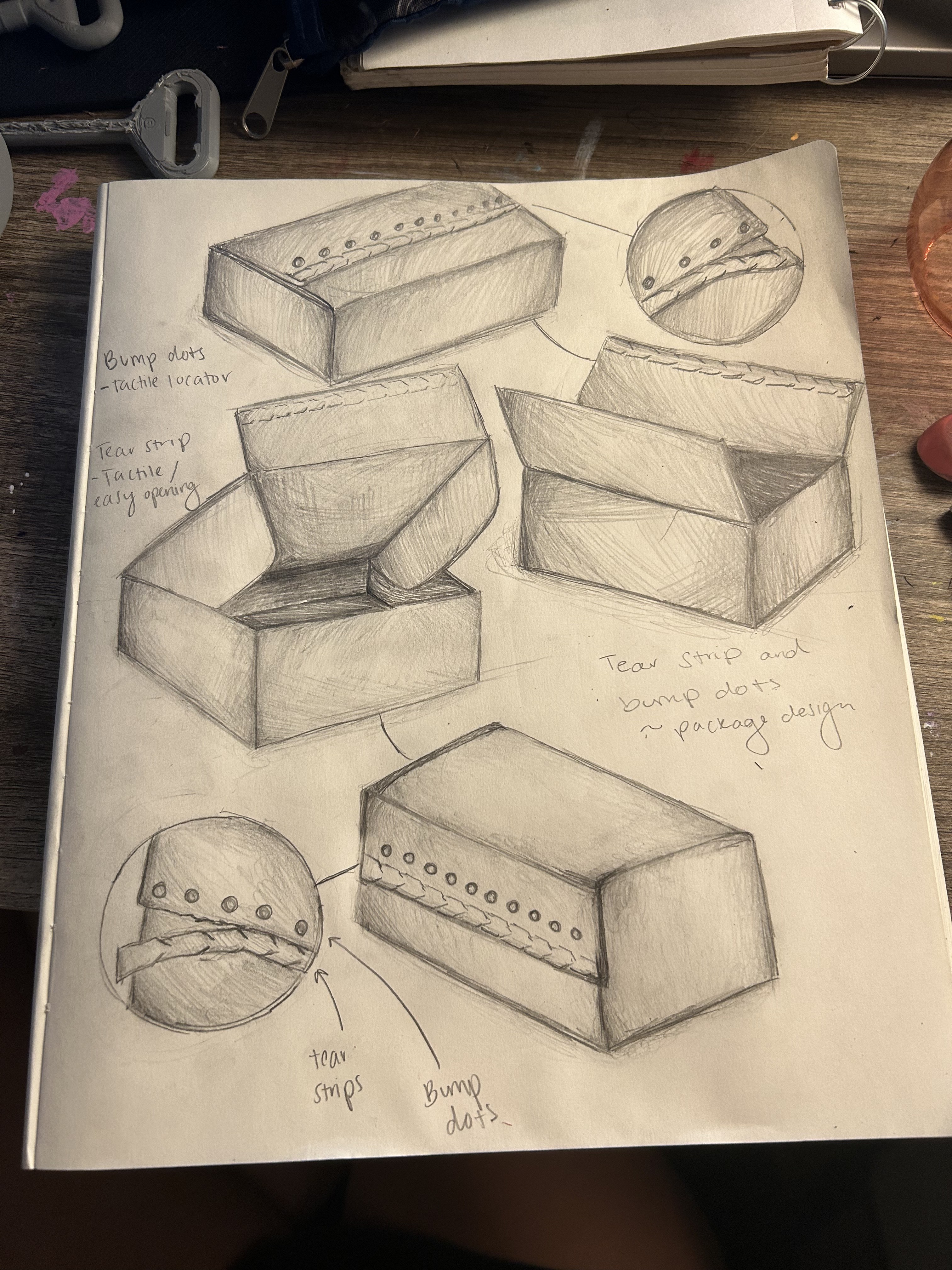

Tactile elements can play a crucial part in a blind person's experience of an object, using sense of touch to help guide a process.

Things like pull tabs, large fonts, high contrast, and different textures can all play a role in creating a better experience for a blind individual.

Gaining insights through research, prototyping, and user testing.

action

In eleven weeks, the package team created 25 different prototypes and gained 35 different insights. We researched successful and accessible packaging, sketched and built an array of packaging prototypes, and testing those prototypes with members of the BLV community.

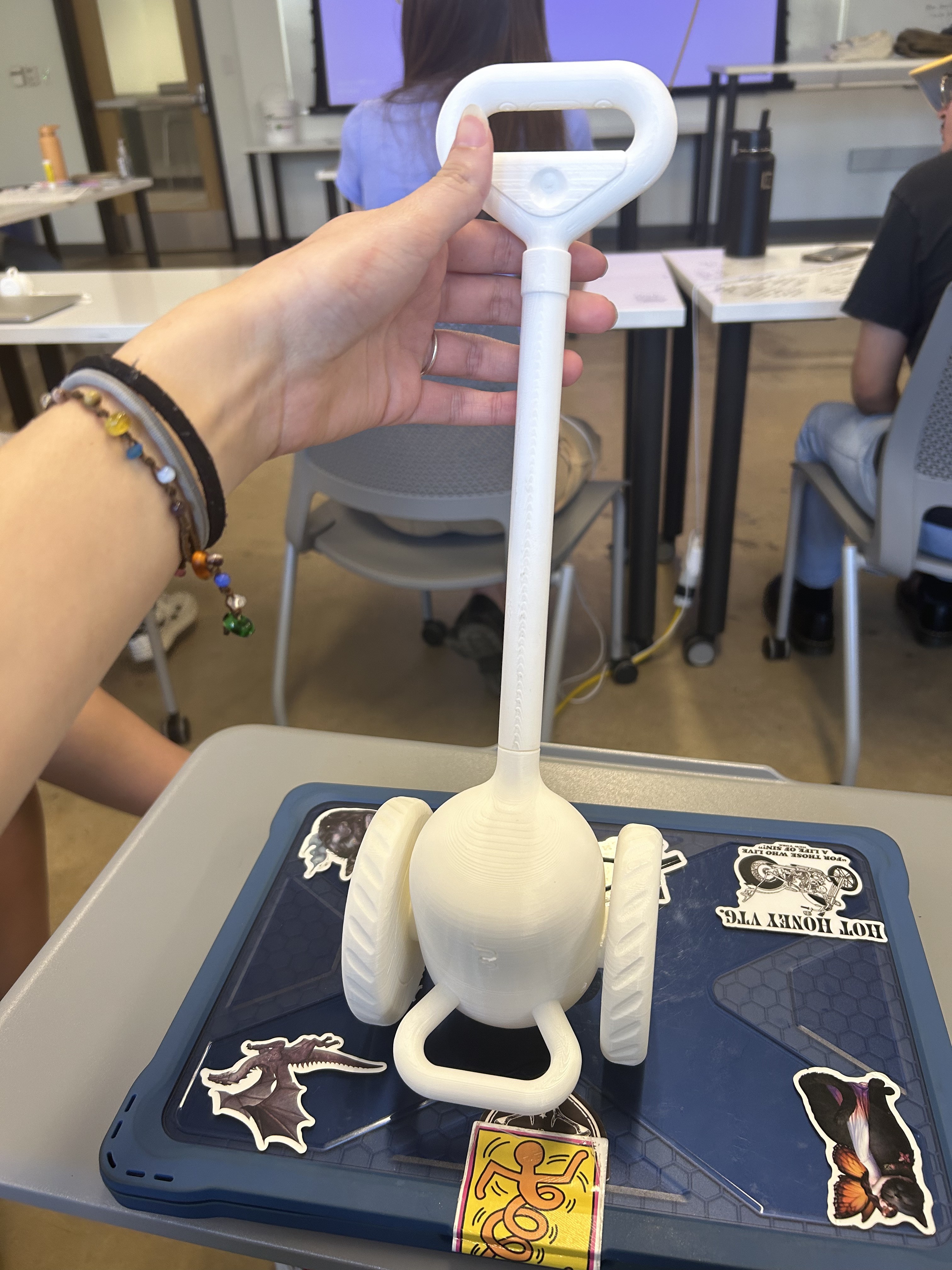

3D Printed Models of the Glide Device

Our team 3D printed quarter size, half size, and full size Glide prototypes to help with packaging ideation.

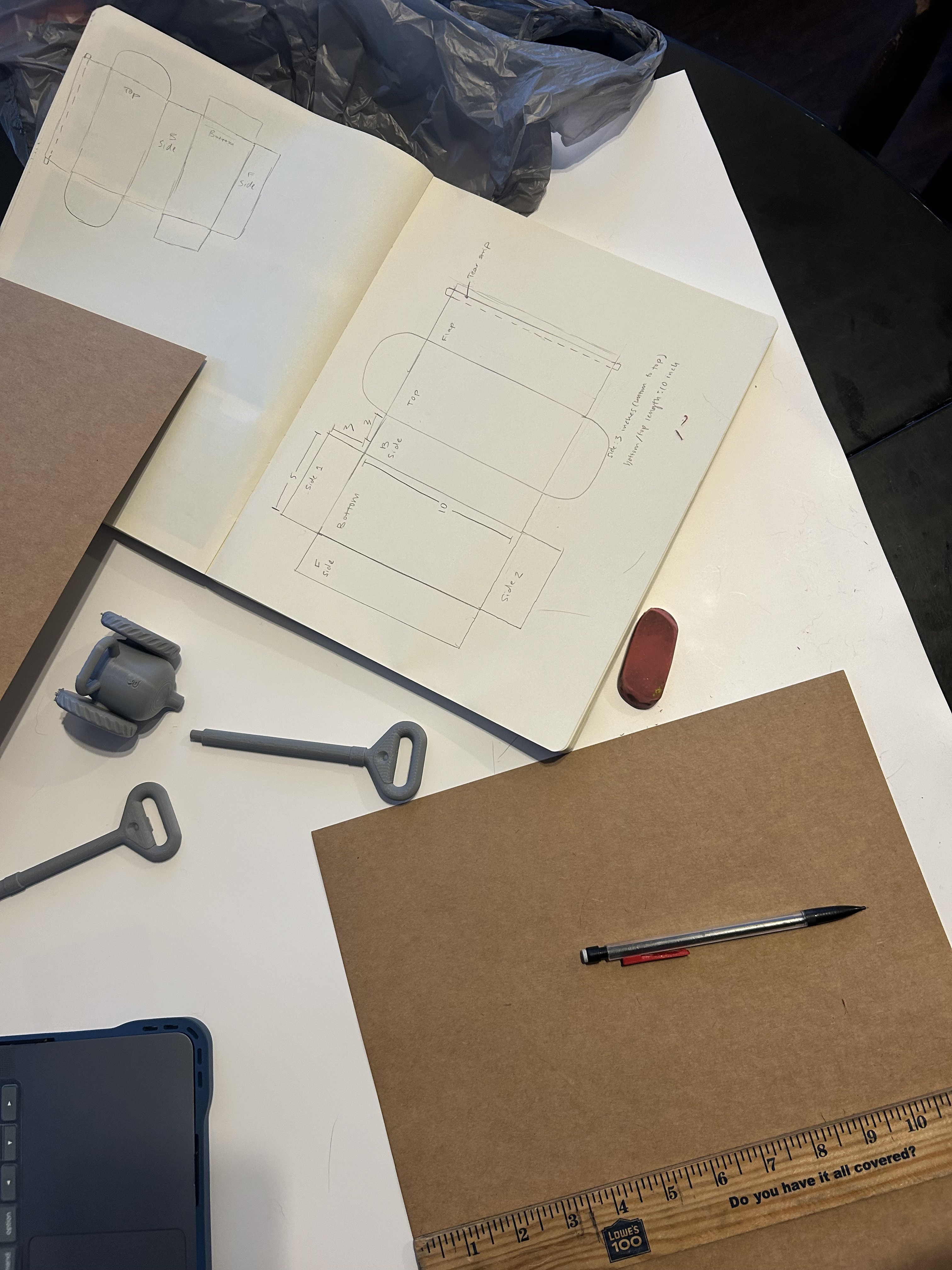

Ideation through sketching ideas and creating dielines

25 prototypes created by our team

As a collective group, our team created a total of 25 prototypes - 15 quarter size, 6 half size, and 4 full size packages to test with blind and low vision users.

User testing our prototypes

We user tested each prototype members of the blind and low vision community. We used 4 success metrics - time to unbox, satisfaction rate, clarity on features, and repackaging ability. They gave us feedback about what they liked and what didn't work.

Meeting with RR Donelley

We got to meet with RR Donnelley, a marketing and packaging firm that gave us insights on material, cost, shipping, and more. After sending them our dielines, they were able to give us an estimate on cost, which ended up being on-budget (<$6).

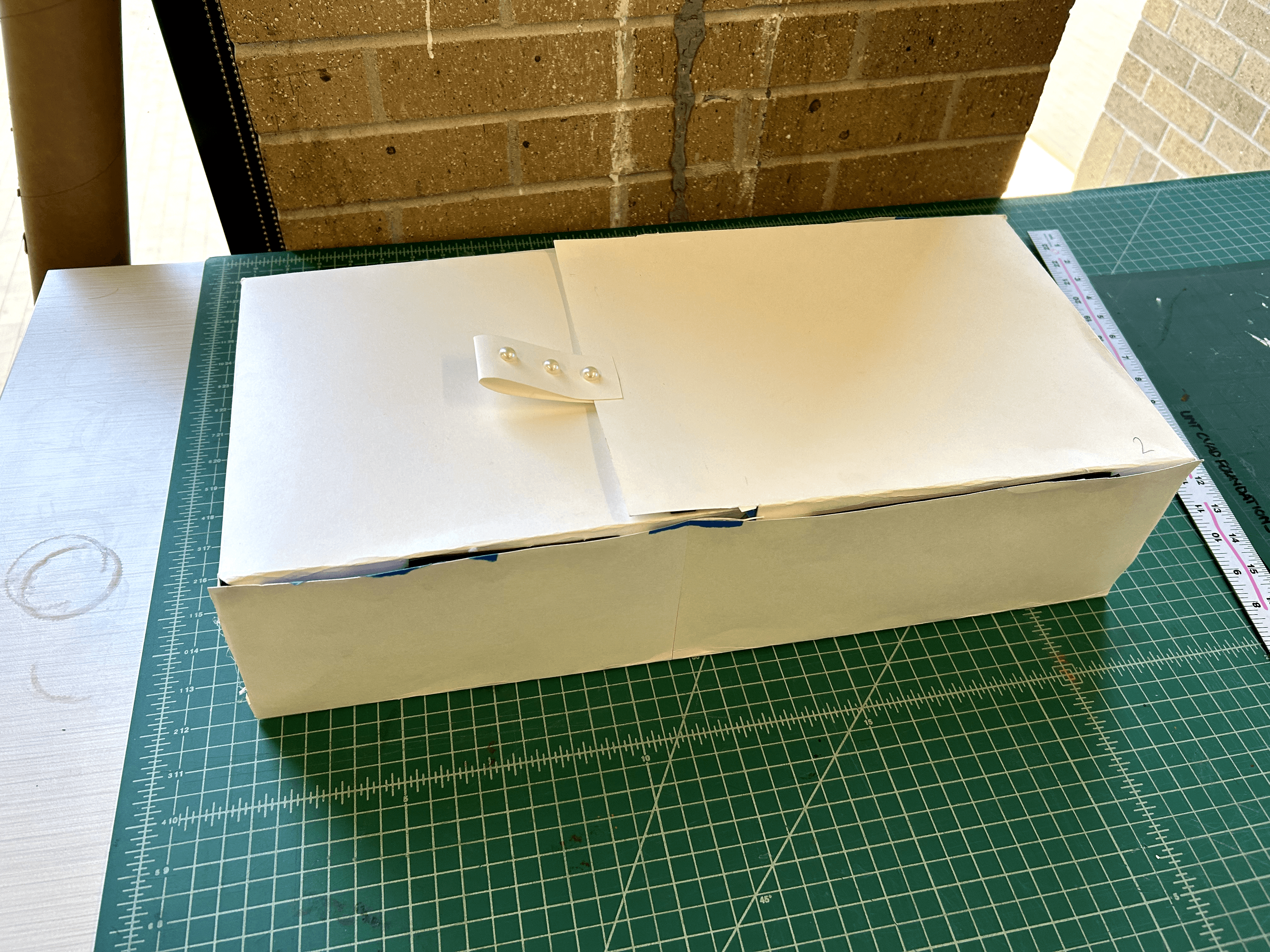

Final prototypes delivered to Glidance

Two members of the Glidance team - Lorien, the product director, and Joel, the UX engineer who is also blind - flew all the way from Seattle, Washington to Denton, TX to try out our packaging prototypes, alongside the digital team's app onboarding. They showed us a Glide prototype, gave us great feedback and we were able to hand off our deliverables, including materials, cost, and research.

Turning 25 prototypes into 2 final results.

results

This experience helped me understand the importance of accessibility in design, and how there are often many more considerations we must pursue as designers to make sure we account for everyone. By the end of the process, our team was able to:

Built 25 total packaging prototypes to test.

Gained insights from 35 total BLV users.

Created two final packaging designs for handoff to Glidance at desired deadline and on budget, no more than $5-$6 per box.

View More Work...

Bridgecrest – UX/UI Design

DriveTime and Bridgecrest – Visual Design

Sacred Roots – Conceptual App/VR Design